What is a universal interface?

Flexible like a “Swiss army knife”, universal interfaces in industrial environments and critical infrastructures are a great way to easily network the field level.

Typical universal interfaces for industrial sensors are:

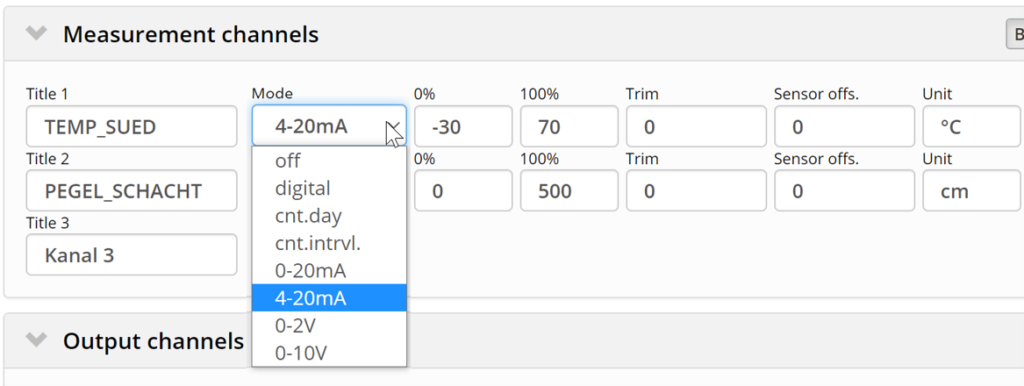

- Analogue/Digital IO: 4-20mA, 0-20 mA, 0-2V, 0-10V, Digital, Counter (S0), PWM

- Bus communication: RS232, RS485, RS422, CAN, Ethernet, BLE

Analogue sensors continue to be widely used worldwide due to their robustness and ease of use in industry.

What’s special about an industrial interface?

The design with connectors and cable clamps visually distinguishes an industrial interface from internal device interfaces. The requirements for the protective measures of an industrial sensor interface are, on the contrary, invisible, but no less important. These enable use in rough environments.

The special feature:

- Insensitive to interfering radiation

- Protection against overvoltage

- Protection against electrostatic discharge (ESD protection)

- Mechanical protection against contact, dust, water defined as IP protection class (international protection)

- Long cable lengths

The robust and most widely used sensor interface standards in the world, such as 4-20mA, are still widely used. Durability and stability are the most important properties for industrial sensors. Often these are installed directly at the place of use or have to be serviced regularly. A practicable and safe connection option is the basic prerequisite for this.

With a flexible selection of interfaces, existing sensors can also be retrofitted very easily, these are so-called “brown field” applications.

Does that make the configuration effort high?

Simple answer: No. Only the most necessary adjustments are made quickly and efficiently on site. The devices work with the selected IoT app and are thus automatically pre-configured.

The installation is completed in a few minutes. The commissioning technician concentrates on the installation and can set both trim and installation height using the app.

What do the universal inputs from Microtronics do in detail?

The configurations can be practicably prepared in the web portal and serve as automatically commissioned templates during commissioning. Thus, the use of sensor technology is not only flexible, but also – as the example above shows – very easy to put into operation.

The universal inputs are designed as follows:

- Each channel can be activated with the desired sensor interface.

- In the basic setting, the scaling and unit are defined.

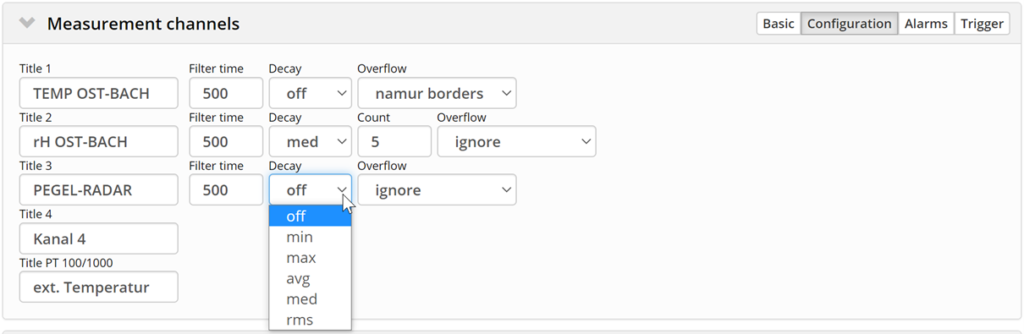

- The measuring unit can be further configured with filters and pre-processing settings.

- Trigger configuration, event management and alarming round off the function library to be ready for use in many applications.

This example shows how easy it is to configure using automated remote configuration of the units. You can combine an open and flexible range of sensors in different compositions, which simplifies on-site deployment.

Learn more about device management here.

Hint: For experienced experts, the application itself can be designed via rapidM2M Studio. Libraries and sample applications help you get started.

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

Special features of the universal inputs

- Overvoltage and input filter circuitry against external interference

- Protection concept or automatic switch-off in the event of reversed wiring or setting of channel options

- Protection circuit for the direct small signal input (0-2V)

Special feature of the self-sufficient EASY series

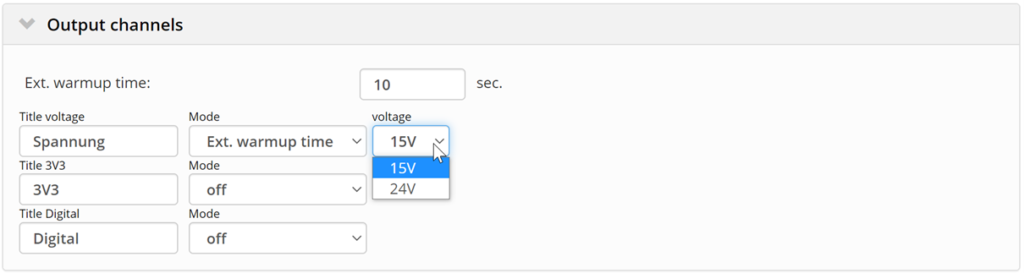

In addition to the measurement processing, the sensor is also autonomously supplied with power from the EASY. It is very important to note that a classic industrial sensor needs a certain amount of time after switching on to provide a stable value.

- The devices offer switchable sensor supply voltages. The required sensor warm-up time can be configured.

- The supply voltage can be set to 15 or 24 volts depending on the needs of the sensor.

For both the robust myDatalogEASY IoT ATEX and the myDatalogEx, the 4-20 mA interface is the most popular. The units have selectable integrated barriers to be used as a feeder. The EASY IoT ATEX can be operated in zone 2 and feed sensors in zone 0.

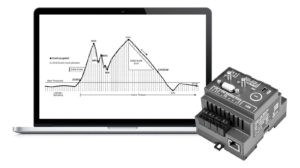

Special feature of the C3 control cabinet series

The rapidM2M C3 product series has three universal inputs on the unit which can be easily supplemented with two different types of expansion modules (input expansion & output expansion).

Three extensions are prepared as standard in the sample IoT apps and ten in the libraries.

Nevertheless, the extremely efficient power consumption of the C3, in its class for networked PLC solutions, with an extremely high-performance CPU is a good mix for modern monitoring, control and regulation applications.

Conclusion: Flexible, efficient and sustainable

The universal interface in the fully integrated device variants establishes a high degree of flexibility and facilitates handling in various situations. In addition, it conserves resources thanks to its energy efficiency and enables reusability, which has a positive effect on sustainability. The ease of use is maintained, is even significantly improved compared to many classic solutions and promises handling without high training costs. The optimisation of the self-sufficient device variants drastically extends the runtime and thus the maintenance cycles. Long-term, stable operation with reduced use of resources – for example staff and number of trips – has a further positive effect on sustainability.