In industrial plants where flammable substances are used, or in environments where flammable gases are produced by natural or chemical reactions, special safety precautions are required when using electronic equipment.

For example, flammable gases can be found in chemical plants, paint factories, where solvents are used, around fuel storage tanks, in power stations, in the oil and gas industry, and in waste water treatment and sewage treatment plants.

These flammable gases are the first of three components required for an explosion. If oxygen is then added, which in most cases is the case due to the natural ambient air alone, only a spark is needed as an ignition source to cause an explosion.

Three components must therefore come together for an explosion:

- Oxygen

- Fuel (e.g. a flammable gas)

- Ignition source (sparks, hot surface, …)

Increased security requirements for IoT hardware

In the use cases mentioned above, there are a large number of possible IIoT (Industrial Internet of Things) applications that can add real value to the respective business model.

For example, you could use predictive maintenance applications to make more effective use of machinery in paint factories, automatically log fuel levels in fuel depots, or monitor the flammable H2S gas produced in the sewer.

The electronics required to record and transmit measurement data can be the missing third component for an explosion due to electrostatic discharge, short circuit or mechanical friction. The hardware is often powered by batteries or rechargeable batteries. These can be a further source of ignition if they are loose, for example.

To ensure that IoT hardware does not become a source of ignition in an environment with oxygen and flammable gases, special design and functional safety measures must be taken during development. These can be found in Directive 2014/34/EU (referred to as ATEX for short).

If you are in a potentially explosive atmosphere, only devices with the appropriate certification may be used. This also applies to smartphones, tablets, etc. that employees bring into the vicinity of the measuring point.

In addition to the equipment itself, which is located in the hazardous area, control and monitoring systems which are located outside the hazardous area but which ensure the operation of the equipment are also covered by this certification.

Classification of potentially explosive atmospheres / ATEX zones

ATEX is the abbreviation for Atmosphères Explosibles. In such an explosive atmosphere, a fuel is present in addition to oxygen. Flammable substances are divided into two categories:

- G = Gas, vapour and mist

- D = Dust

The ATEX directive distinguishes between 4 zones:

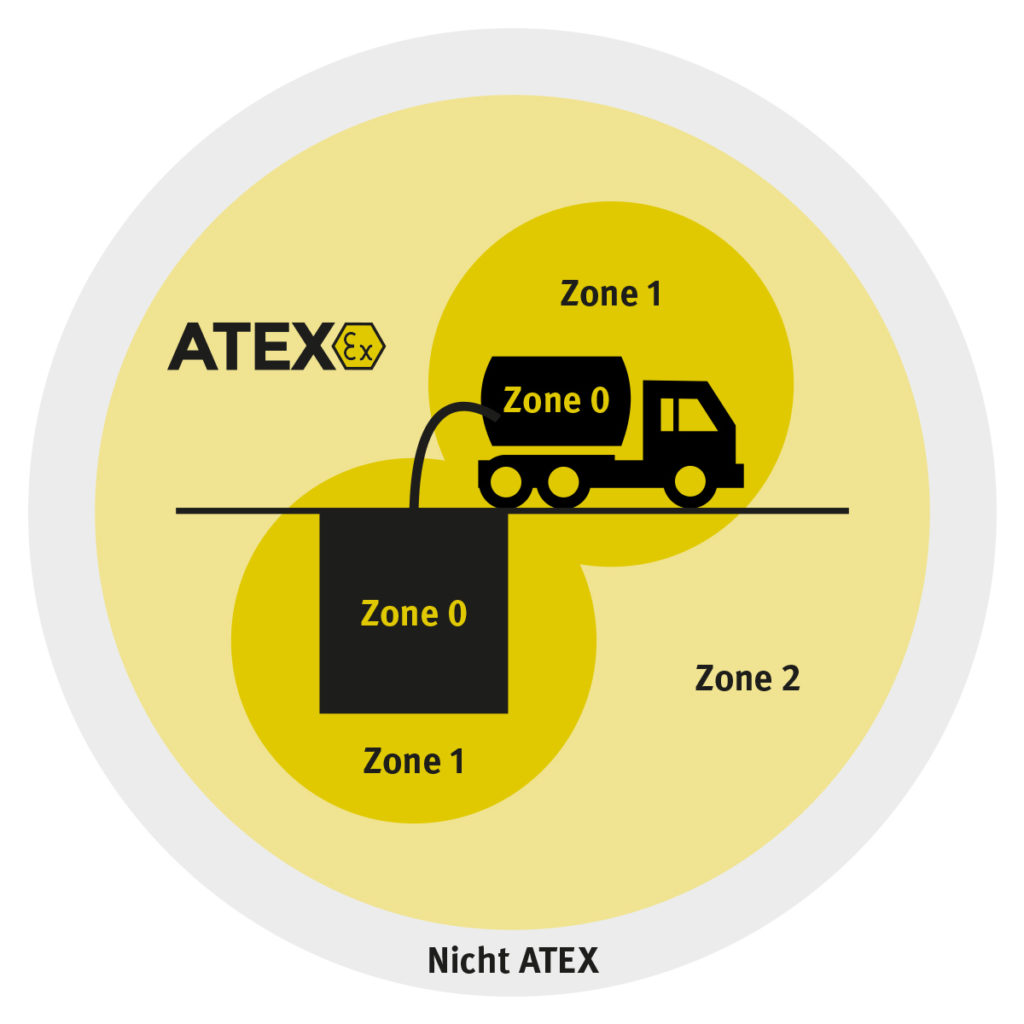

- Zone 0: In normal operation, oxygen and a flammable gas are present frequently and for long periods of time. “Frequently” means that this hazardous mixture is present for more than 50% of the operating time. “Longer” means more than 1000 hours per year.

- Zone 1: The mixture of oxygen and flammable gas is occasionally present during normal operation. Occasional” is defined as less than 50% of the operating time and a total duration of between 10 and 1000 hours per year.

- Zone 2: A mixture of oxygen and flammable gas does not occur during normal operation, or if it does, then only for a short time (less than 10 hours per year).

- Non ATEX: The environment is not potentially explosive and the products used do not require certification.

IoT device for ATEX Zone 1

With myDatalogEX, Microtronics offers an all-round device for data acquisition in ATEX Zone 1. myDatalogEx acquires signals from industrial sensors. When selecting the sensors, you must ensure that they are also certified for ATEX Zone 1. The recorded data is processed and sent to a central web platform via cellular.

With the gateway you collect data from remote sensors in ATEX Zone 1 and send it to the web platform. It is also important to ensure that the sensors are certified for ATEX Zone 1.

Ready-to-use ATEX applications include H2S or level measurement, but almost any other application can be realised with the Microtronics ATEX certified system.

The myDatalogH2S is used to measure combustible H2S gas. Like petrol or diesel, H2S belongs to temperature class T3. The myDatalogH2S transmits data via short-range radio to a smartphone within range with the GasBuster app installed, or via 3G to the IoT platform. If you want to query the data with your mobile phone, make sure that it is also approved for the respective ATEX zone in which you are located. The range is up to 15 metres. ATEX zones must be clearly labelled with appropriate signs at the measuring point.

Use the myDatalogGauge for level measurement in ATEX areas. The application consists of a gateway and up to two ATEX-certified pressure probes for measuring the fill level. The pressure probes communicate with the gateway via short-range radio. The gateway then transmits the data via 3G to the central, web-based IoT platform.

Your application in the ATEX zone

Would you like to record, edit and transfer data in the ATEX zone?

Contact the Microtronics team, we will be happy to advise you and ensure your safe Industrial IoT application in potentially explosive atmospheres.