Inteso

Valve Monitoring of Vacuum Sewer System

What's the solution about?

Vacuum sewerage systems are an alternative to conventional sewerage systems. They are often used in difficult subsoil and unsuitable ground conditions (bog, rock, etc.), insufficient gradient, sparsely populated areas or rapid urban expansion.

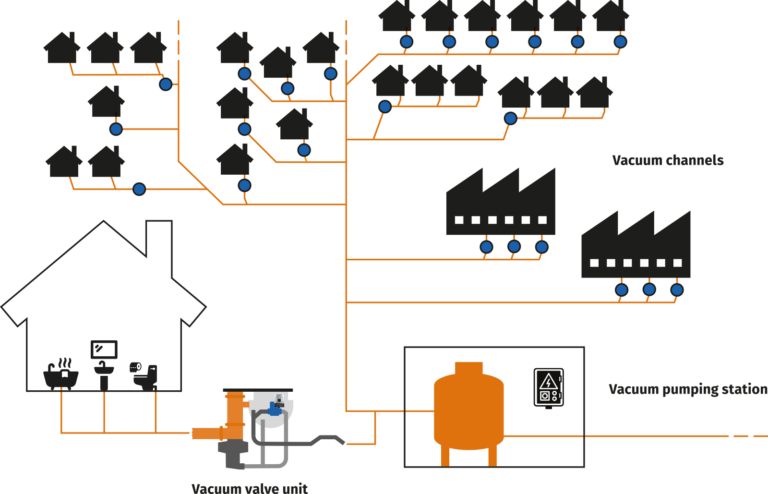

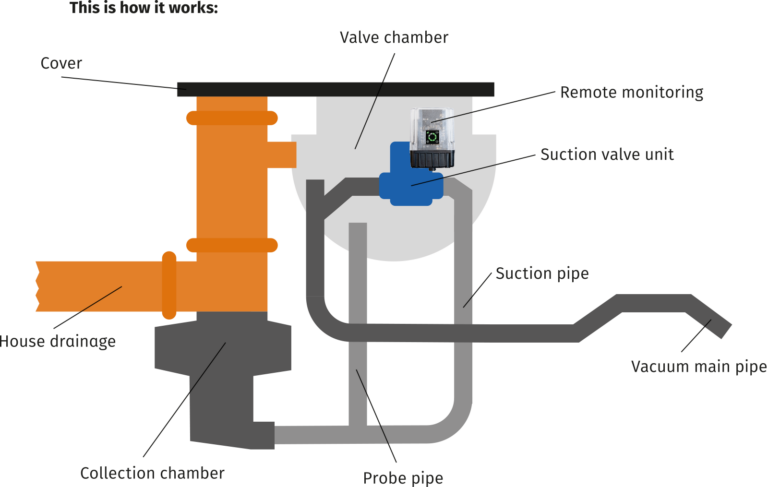

A vacuum sewer system is a closed pipe system. It is kept under constant negative pressure with vacuum pumps. Each house connection has a transfer shaft in which the wastewater is collected. When a certain volume of wastewater is reached, the valve of the vacuum chamber opens for a few seconds. Due to the negative pressure in the pipework, the wastewater is extracted and transported to a vacuum pumping station. From here it is then transported to the sewage treatment plant.

The challenge

One of the most common faults in a vacuum drainage system are suction valves that no longer close completely. This can be caused, for example, by objects that have been flushed down the toilet. As a result, air constantly enters the pipework and the pumps can no longer generate the required vacuum. Malfunctions such as pressure loss or valve damage to the vacuum extraction valve also result in increased energy consumption of the central vacuum supply system. The problem area or the faulty suction valve is difficult to localise. This is usually checked during quiet operating times – during night shifts. Depending on the size of the system, there are hundreds or thousands of suction valves per vacuum sewerage system, which are scattered across the entire urban area. Due to the complexity of the distribution in the drainage area and the time-consuming maintenance, this results in a high expenditure of personnel resources.Valve monitoring

In general, vacuum sewerage systems are equipped with monitoring and control systems that provide an overview of the operating status. There is usually no dedicated monitoring of the individual vacuum extraction valves at each house connection. Continuous monitoring of the vacuum extraction valves in the transfer shaft using an easy-to-install remote monitoring system eliminates the time-consuming search for pressure losses and significantly optimises the deployment of personnel. The valve monitoring of the vacuum extraction valves is equipped with a patented digital sensor, the so-called DigIn sensor. This recognises the valve position and detects leaks (leaking diaphragms). With the myDatalogMINI data logger, the measurement data is regularly transmitted to a central web platform. This monitoring solution significantly reduces maintenance costs. In addition, it allows a quick response time with more targeted deployment of personnel to problem cases. Furthermore, incorrectly connected rainwater drains and a permanently running tap can be detected by opening the valve too often. The advantage of permanent monitoring provides transparency over the entire system, the operation of the outstations and the possibility of preventive maintenance.These components are used

Founded in 2010, INTESO is an electrical engineering service provider with a focus on

measurement, control and automation technology.

Inteso has decades of experience in the planning, construction and support of plants and also offers: Service and maintenance work, troubleshooting, adaptation to the state of the art and safety inspections

-

Pulvermühlweg 15

3250 Wieselburg

Austria - office@inteso.at

- +43 676 7777 132

- www.inteso.at