Digital Moulds

Mould Monitoring - Monitoring of injection moulds

What's the solution about?

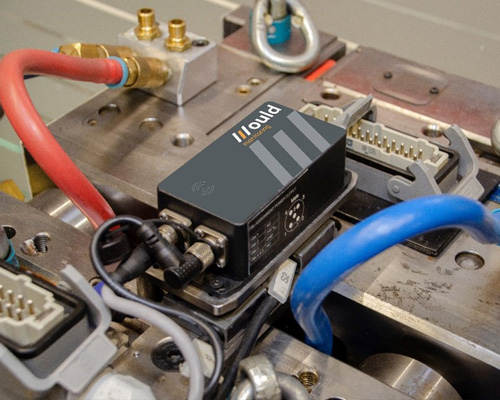

Digital Moulds offers Mould Monitoring; an innovative muold monitoring system. It is easy to install and enables active and comprehensive control of injection moulds. Real-time data transmission allows a quick response to deviating parameters.

Mould Monitoring is installed at an early stage on the injection mould, according to the Plug & Play principle. This condition monitoring system allows, from the first idea to the retirement, an accurate recording of the data.

Mould Monitoring creates more transparency in data exchange. Managers across multiple tiers leverage Digital Moulds’ basic and professional capabilities for a holistic approach to solutions. With the tool monitoring system, you achieve simple planning along the entire value chain.

With the help of condition monitoring systems, you can more easily identify and avoid bottlenecks, downtimes or production losses. Scrap rates, missing parts or quality costs can thus be reduced and the quality of the components maximized.

Mould Monitoring therefore provides more

- Planning accuracy

- A target-oriented demand and inventory planning as well as

- Better compliance with delivery times along the entire supply chain.

Critical changes are more easily detected with the help of a condition monitoring system. Downtimes can thus be planned. In addition to this tracking function, Digital Moulds also offers other products.

These components are used

The first talks on Digital Moulds took place in 2015, and Digital Moulds GmbH, based in Sierning, Austria, was then founded in 2019. Our Moulding Solution is a product of the experience of the Haidlmair Group as a toolmaker and the Bavarian toolmaker Siegfried Hofmann.

The Haidlmair and Hofmann groups of companies have high-tech production processes that they have been able to build up as a result of decades of research, development and partnership.

With this user know-how from mold making and production processes, they create an excellent solution for a digital mold management system with their moulding solution.

Mould Monitoring is the answer to the challenges of plastics production. It allows active and comprehensive documentation of the mould in the injection mouding process. This means that no matter which moulding solution companies choose, their production is cost-efficient and environmentally friendly.

You just need the right data for it. Data on mould status such as operation, storage or transport, or on deviating process parameters such as pressure or temperature. Digital Moulds stands for real-time data, seamless documentation and intelligent injection moulding production.

-

Ruthnergasse 20

4522 Sierning

Austria - office@digitalmoulds.com

- digitalmoulds.com