There are these terms that keep popping up around ATEX. Nevertheless, one often does not really know what is behind it. We shed some light on the darkness and explain the most important terms around the topic of “intrinsic safety”.

Where am I allowed to install?

The whole topic around ATEX and corresponding guidelines is primarily aimed at all EU member states. To this end, the European Union has defined the ATEX Operating Directive and the ATEX Product Directive in the ATEX Directive.

The ATEX Product Directive 2014/34/EU contains the rules for placing devices and products on the market in potentially explosive atmospheres. It concerns electrical as well as non-electrical devices, machines and components.

The ATEX Operational Directive 1999/92/EC defines the minimum requirements for explosion protection and the safety of workers who may be endangered by explosive atmospheres. This means that anexplosion protection document must be drawn up as part of the risk assessment. Based on this document, there are now areas where an explosion hazard can occur (ATEX zones).

| Explosive atmosphere … | ATEX zone | Device category | Protection level EPL | Applicable in the zones | |

| in the form of Gases, Vapours & Mists | |||||

| Constantly available | 0 | 1G | Ga | 0, 1, 2 | |

| Occasionally present | 1 | 2G | Gb | 1, 2 | |

| Available for a short time | 2 | 3G | Gc | 2 | |

| in the form of dust | |||||

| Constantly available | 20 | 1D | Da | 20, 21, 22 | |

| Occasionally present | 21 | 2D | Db | 21, 22 | |

| Available for a short time | 22 | 3D | Dc | 22 |

What am I allowed to install?

As briefly described above, the equipment category and the EPL (Equipment Protection Level) are important information for the user, as it is very easy to read from them in which areas the equipment may be used.

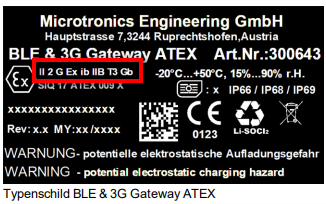

This information is hidden in the marking on the ATEX certificate (= EC type examination certificate) and also on the type plate of the equipment.

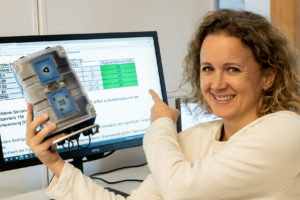

In the case of the Microtronics device BLE&3G Gateway ATEX, it can be seen that the device has the EPL Gb and is therefore allowed to be installed and operated in zones 1 & 2.

Further important parameters in the marking of the equipment are

- ignition protection type

- Explosion group

- Temperature class

The last two parameters (temperature class and explosion group) are directly related to the prevailing explosive media in the case of explosive vapours and gases.

The temperature classes (T1 – T6) define the maximum surface temperature at any point in the unit (in normal operation or in the event of a fault). This is therefore always lower than the ignition temperature/flash point of the respective gas/liquid.

The explosion group, on the other hand, defines the classification according to the minimum ignition energy (e.g. by a spark) for these gases in three groups (IIA / IIB / IIC).

| Explosion group | Temperature classes | |||||

| T6 (up to 85°C) | T5 (up to 100°C) | T4 (up to 135°C) | T3 (up to 200°C) | T2 (up to 300°C) | T1 (up to 450°C) | |

| I/A (300µWs) | Petrol Diesel Heating oil … | Ethyl alcohol … | Acetone Ammonia Propane … | |||

| I/B (150µWs) | Hydrogen sulphide | Ethylene | Town gas | |||

| I/C (50µWs) | Carbon disulphide | Acetylene | Hydrogene | |||

Now an example

From the above table, in which the best-known gases are entered, the following minimum requirement can be defined for the gas hydrogen sulphide in the special case of the myDatasens H2S application with the BLE Gateway: -> Explosion group IIB and temperature class T3

Furthermore, it can be stated that the hazardousness of the gases

- increases from explosion group IIA to IIC or

- for the temperature classes from T1 to T6.

The demands on the equipment increase accordingly.

The third important parameter is the ignition protection typeof the device.

In our case, the ignition protection according to the rules of intrinsic safety “ib” with the EPL Gb.

(= application in ATEX zone 1).

The basic principle of intrinsic safety is based on limiting the amount of energy in a circuit to a non-flammable level. Sparks or thermal effects can therefore no longer be sources of ignition.

How may I install?

The most important thing when installing equipment with the ignition protection type “intrinsic safety” is the proof of intrinsic safety.

The following table/checklist must be used to provide evidence:

| Electrical parameters (according to EC type-examination certificate) | |||||

| Associated equipment | cables and lines | Intrinsically safe equipment | |||

| max. Output voltage | Uo | <= | Ui | max. Input voltage | |

| max. Output current | Io | <= | li | max. Input current | |

| max. Output power | Po | <= | Pi | max. Input power | |

| max. External inductance | Lo | >= | Lc (Cable inductance) + | Li | max. inner inductance |

| max. external capacity | Co | >= | Cc (Cable inductance) + | Ci | Max, internal capacity |

This means that a feeding (= supplying) device cannot supply so much electrical energy to the associated equipment (e.g. measuring probe) in any operating state (incl. fault cases) that an electrical overload can occur.

Conclusion

With the appropriate information on ATEX basics, correct installation and commissioning of a piece of equipment is no longer rocket science.

With the easy-to-use and intrinsically safemyDatasensH2S we have a robust and safe IoT solution for gas measurement in ATEX Zone 1.