What is OPC?

OPC is a collection of standards in the industrial environment and enables uniform access to a wide variety of machines, devices and other systems. With the implemented support for the OPC client, SCADA (Supervisory Control and Data Acquisition) system developers no longer have to support countless drivers for different devices and device manufacturers can make their products usable for users of all SCADA systems by adding an OPC server. OPC is particularly important in the context of Industry 4.0. The standard (IEC62541) is managed by the OPC Foundation.

What is OPC-UA?

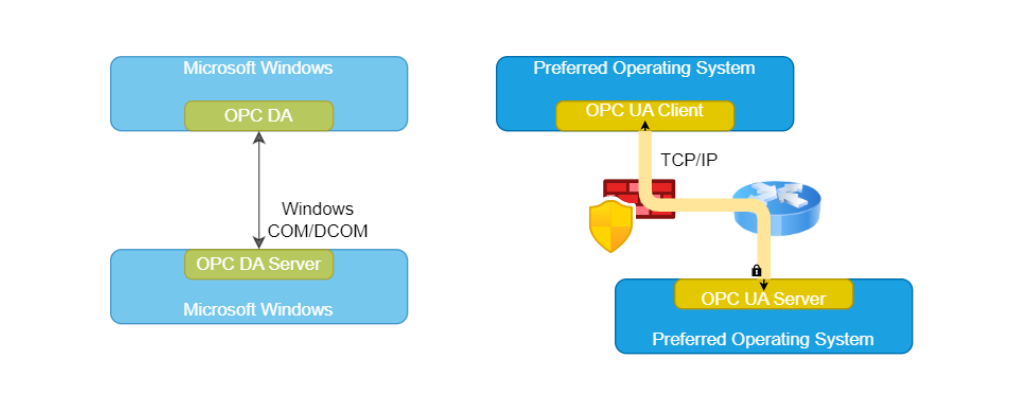

OPC-UA is the current successor of OPC – today also referred to as OPC-Classic. The abbreviation “UA” stands for “Unified Architecture”. While OPC-Classic was dependent on basic Windows technologies, OPC-UA is based on TCP/IP and can be used independently of the operating system. The following figure shows essential differences between OPC-Classic and OPC-UA.

The fixation on Windows was a weakness of OPC-Classic and also limited the spread to other operating systems (e.g. Linux). Therefore, platform independence was one of the primary goals of OPC-UA. The changeover to TCP/IP also has the advantage that communication can now be routed through common firewalls and thus more control of communication is possible. OPC-UA has also been further developed in the security area and offers various options for authentication and encryption.

myDatanet OPC-UA Server

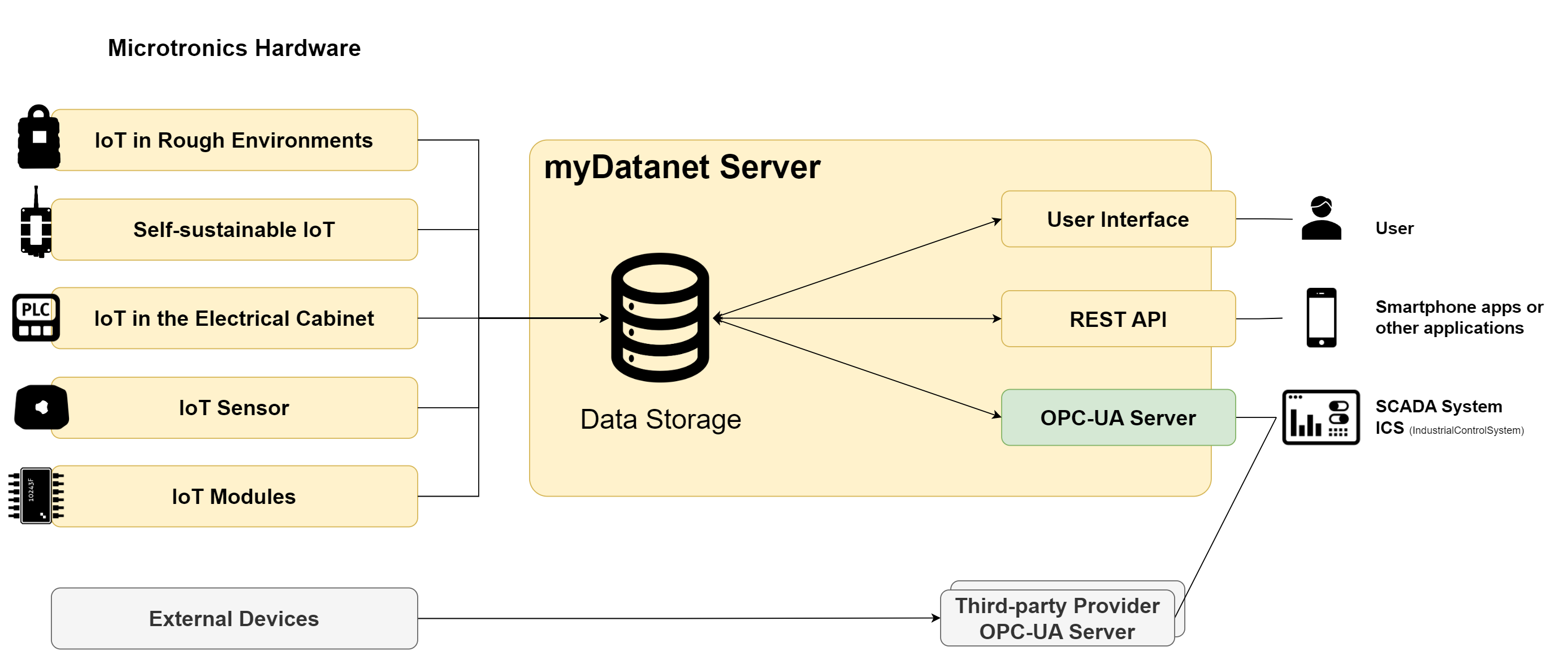

Due to the many advantages, an OPC-UA server was developed for the myDatanet platform. myDatanet OPC-UA is available from server version 50v012 and can be optionally (also subsequently) activated.

This means that Microtronics partners can easily forward the captured and transmitted data fields to any SCADA system, thus generating an even better solution for their customers.

Implementation

OPC-UA-DA

The abbreviation “DA” stands for “Data Access” and is the basic function expected from OPC. With “DA”, individual data fields and their value can be accessed. In the case of myDatanet OPC-UA, read access to last valid measured values as well as read and write access to configuration values can take place. The nature of the measuring point determines the data fields that can be retrieved without any additional configuration effort.

OPC-UA-HDA

The abbreviation “HDA” stands for “Historical Data Access” and makes it possible to read out time series of data fields. Since historical data is available in myDatanet, myDatanet OPC-UA supports this function. In addition to the data field, the client can pass a time period and receives the existing data in return.

Authentication

The authentication of the OPC-UA clients is linked to the myDatanet user administration. This fully integrates rights management and facilitates security management. The user used for authentication has the same rights as when logging in to the myDatanet UI (such as visible sites/customers).

Features of myDatanet OPC-UA

- The OPC-UA-HDA standard – retrieving historical data – is supported.

- The customer can build on the reliable rapidM2M communication and integrate devices directly into an industrial environment or into OPC-UA compatible visualisations.

- Multiple use of the collected data: via the myDatanet UI, the API or also an OPC-UA based visualisation.

- Makes the proven myDatanet device and data quality available in OPC UA-compatible clients (such as SCADA systems like WinCC) without programming effort.

Handling the Publish Interval

The so-called Publish Interval is a negotiated property of each individual registration or each individual registered data point of a client. This is the minimum time interval that the server must wait between the publication of 2 different values (timestamp + value + quality[StatusCode]).

Negotiation process (defined via the OPC UA standard): The client sends a desired Publish Interval to the server when registering each individual value. The server can either accept or change this value and then sends the actually applied Publish Interval back to the client. The server may have defined upper and lower limits to which the value is corrected if necessary. In myDatanet, these limits are fixed between 5ms and 1 second .

If several clients are connected to an OPC UA server and have registered the same field, the largest publish interval is used. Internally, the data is always updated synchronously; it is not possible to adhere to the publish intervals of the individual registrations.

Configuration example

A detailed example of the configuration on the myDatanet server and the OPC-UA client as well as the display of data in the OPC-UA client can be found in the Microtronics Academy.

Best Practice

Four best practice examples of successful integration into your own process control or SCADA system are available here.

First published in December 2020, last updated in July 2024