This article is all about the density measurement of the sensor modules. Resistance to water and dust is essential to ensure the protection classes.

To check this …

each individual sensor module is tested in Microtronics’ in-house production department during the final test to see whether it is also tight after assembly and the ultrasonic welding process, in which the cover is welded to the lower part of the housing.

By applying a vacuum to special openings in the housing (which are subsequently sealed), a vacuum is created inside the sensor module which, if maintained, provides information about the tightness of the sensor module. For this purpose, there are various mounting adapters for our products, which are also manufactured at Microtronics with the aid of the 3D printer.

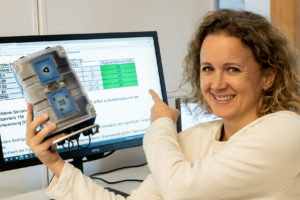

The vacuum tester

To facilitate this testing step, a special “vacuum testing device” has now been built, where only a few buttons have to be pressed to get the result.

Thanks to the integrated dual-channel system, the tester has a choice of two different pushers with which the test specimen is ultimately subjected. This is also intended so that you can use a second channel for other settings, and thus other products.

After selecting the test pressure, the “Start test” button can be pressed and the device will output the corresponding negative pressure at the outlet. This is now shut off by a solenoid valve and held for 10 seconds. During this time, an LED lights up to symbolise to the examiner that the test is in progress. If the applied negative pressure does not drop during this time, the test is considered passed.

Since the control system is programmable with Python, the test sequence can be adapted and improved at any time.