RetroFeel™

Predictive maintenance with sensor-based solutions

What the partner solution offers

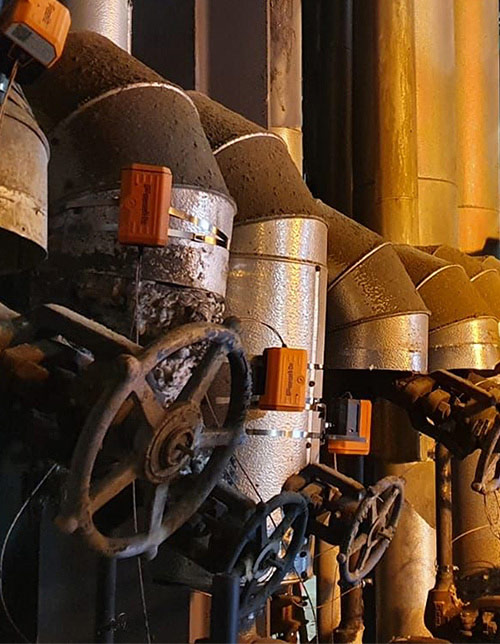

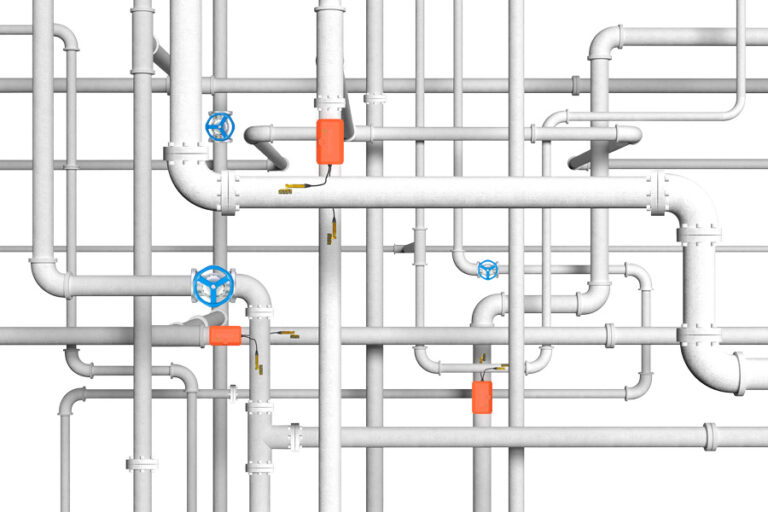

RetroFeel™ senses structural change in mechanical parts and systems and provides advance warning of impending failures. Unplanned downtimes are thus minimised and the use of resources optimised.

The sensor-based solutions, provide real-time insights into the management of critical industrial assets in production processes. For this, a wireless edge device and stick-on sensors printed with nanotechnology are attached to the mechanical parts of the plant. The easy-to-integrate myDatalogEASY IoT GW ATEX is used to read out the DAUs and transfer the information to the cloud. On the cloud, Feelit carries out further extensive analyses.

The industries in which Feelit products are used are diverse: Oil & Gas, Water & Wastewater Treatment, Energy & Power,Pharmaceuticals, Food & Beverages , Chemicals, Building & Construction, Paper & Pulp, Metals & Mining, Others

These components are used

Feelit is an Industry 4.0 company operating in the field of Predictive Maintenance, which is integral for sustainable smart manufacturing, and better supporting value creation. Feelit automatically alerts of upcoming failures in real-time, preventing unscheduled downtime, and contributing to the efficient use of resources by ensuring optimum system availability.

-

13 Hayetzira St.

2066 720 Yokneam Illit

Israel - www.feelit.tech