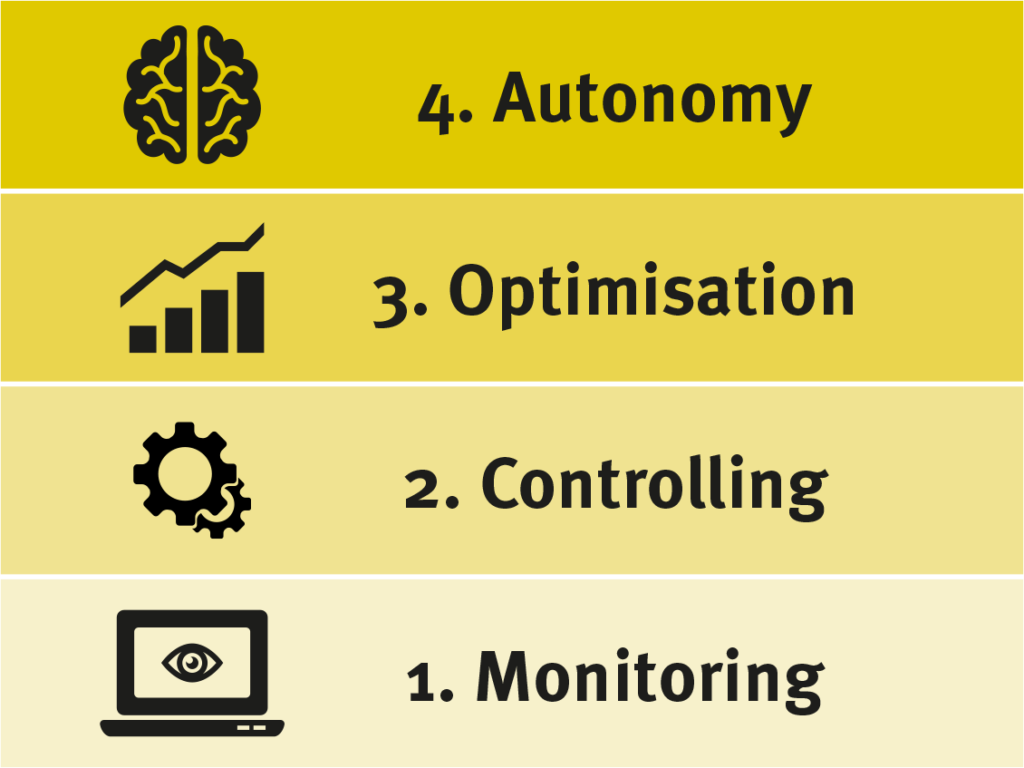

Adding smartness and connectivity to existing product characteristics introduce new fields of application and features that can be differentiated into monitoring, controlling, optimisation and autonomy. Every feature provides the basis for its following feature in the hierarchy (Monitoring, Controlling, Optimisation and Autonomy).[1]

Thus, for providing controlling features, monitoring features must be implemented as well. It is the company’s responsibility to decide which set of functions should be implemented when enhancing their products to smart, connected products in order to create value for the customer. Thereby, options for the innovation of the business model are achieved as well.

1. Monitoring

Smart, connected products enable extensive monitoring of the device state, the external environment, the operating state and the user behaviour by the usage of the internal sensors and the inclusion of external data via interfaces. The analysis of this data using an application directly on the smart, connected device or in a cloud enables the alerting or notification of the user or others in case of changed conditions or changed product performance.

The analysis of the device state, the operating state and the usage over the time period allows the manufacturers as well as the customers an insight into the actual usage of the product.[1]

Manufacturers can use these insights to adapt their business model. With the aid of the available information, the product characteristics and the value proposition can be adapted to the actual customer demands (reduction of over-engineering) as well as raise the quality of their services. Based on the available information on the device state, the replacement parts for repair can be determined in advance. As a consequence, the dispatched technician can often remedy the problem the first time he arrives at the customer site.

Additionally, the analysis of the available usage patterns enables the identification of new types of customers and thereby a more specific definition of market segments. Monitoring also allows an exposure of guarantee compliance problems as well as new sales potentials, for example the demand of additional product capacity, which is recognisable by a particularly high workload.

In some applications, monitoring constitutes the core element of the net product.[1] Micca, for example, offers “EMO”, a system for the monitoring of the power cable temperature of high voltage overhead transmission lines.

2. Controlling

Smart, connected products can be regulated either by commands from afar or algorithms run directly on the product or in a cloud. Algorithms are rules specifying the reaction of the product to changes in its state or environment (for example, if the traffic in the tunnel tube exceeds a critical level, additional ventilation should be activated). The controlling by using software embedded in the product or run in the cloud permits individual modification of the device performance in a degree previously impossibly unprofitable.[1]

In the past, the mechanical components primarily determined the performance of combustion engines, whereas now companies like the manufacturer of agricultural machines “John Deere” migrate to producing standardised engines and vary the performance only via software.[2] That same technology enables users to individualise and control their actions in many ways using a smart, connected product. Philips’ lighting system “Hue”, controllable via a smartphone application, serves as an example. Via smartphone, you can turn the lights on and off, adjust their colour temperature or program them so in the morning, they softly increase their brightness to the maximum.

3. Optimisation

Thanks to monitoring, extensive data is available. If these are linked to the possibility of controlling product features, new ways for optimising the product performance are opened up, which had not been feasible before. By the application of analyses and algorithms on current and historical data smart, connected products can drastically improve their capacity, performance and efficiency.[1]

The console unit of a wind turbine can, for example, permanently readjust its rotor blades to gain maximum energy from the available wind power. Simultaneously it considers the consequential influences on adjacent turbines and correct the adjustment accordingly to increase the maximum efficiency of the entire wind farm.

The available real-time data and the existing controlling features allow the company to optimise their position in its services by conducting preventive maintenance work in case of an impending product malfunction and repair work via remote access. This leads to reduced downtimes as well as a reduced necessity for sending maintenance engineers.

Even if the detached duty of service personnel for repair works on site is inevitable, the available information enables an exact determination of the required parts and how the problem is solved best beforehand. On one hand, this reduces the arising costs and on the other hand increases the rate of problems solved on the first arrival.[1]

Many of the smart, connected products allow updating the software via remote access, for example if the function extensions are necessary for optimising the product performance.

4. Autonomy

If monitoring, controlling and optimisation functions are combined, smart, connected products reach a never before seen level of autonomy. The vacuum robot “Roomba” by the company iRobot serves as an example for autonomic operation. It uses sensors and software in order to orientate in rooms with different layouts.

Sophisticated smart, connected products possess the ability to capture their environment and understand their own need for service as well as adapting to the users’ preferences. Autonomy not only allows for a reduced demand for operating personnel, but also an obvious improvement on security in dangerous environments and a facilitation of operation in remote locations.[1]

Depending on the degree of implementation, smart, connected products are able to operate co-ordinately and complement each other, which creates a smart environment exceeding the provided isolated functionality in conventional products.[3] Increasing the number of products connected with each other may exponentially raise the value of such a smart environment. For instance, the energy efficiency of the power supply system may be improved by adding smart meters, whose data enable a suitable response to the respective usage patterns.

On the highest level of autonomy, the smart, connected products operate completely autonomously by applying algorithms for the handling of information about their own performance and their environment and the activities of other products and systems, and use their ability of communication with other products.[1] In this case, the operating personnel is solely responsible for observing the performance of the collective of smart, connected products.

Reference List

- ↑ Porter, M. E., & Heppelmann, J. E. (2014, November). How Smart, Connected Products Are Transforming Competition. Harvard Business Review, S. 67–68.

- ↑ Porter, M. E., & Heppelmann, J. E. (2015, Oktober). How Smart, Connected Products Are Transforming Companies. Harvard Business Review, S. 64–88.

- ↑ Mayer, P., Volland, D., Thiesse, F., & Fleisch, E. (2011). User Acceptance of „Smart Products“: An Empirical Investigation. Proceedings of the Zurich international conference on Wirtschaftsinformatik, S. 1063–1072.

Series: Moving into a new business era with smart, connected products

Part 1: Introduction

Part 2: The importance of business model innovation

Part 3: Laying the foundation through strategic decisions

Part 4: Breaking the valid industry logic

Part 5: 5 value stages of an IoT application

Part 6: Transforming the value chain

Part 7: The value generation of things in the Internet of Things

Part 8: Fundamental design of smart, connected products

Part 9: Requirements for the technological infrastructure in the Internet of Things

Part10: Creating added value by advancing to smart products