The Gateway has been developed with its robust rubber amour for the use in harsh environments. For example, it is used in the H2S application in the sewer tunnel.

You think that a sewer tunnel is not a nice working environment? You are probably right. However, for our Gateway, things are getting worse that day.

In the test laboratory of TÜV Süd, it was put through its paces and had to endure a lot. It was exposed to dust and water, even high-pressure cleaner. As a small spoiler, we would like to tell you that it passed all tests.

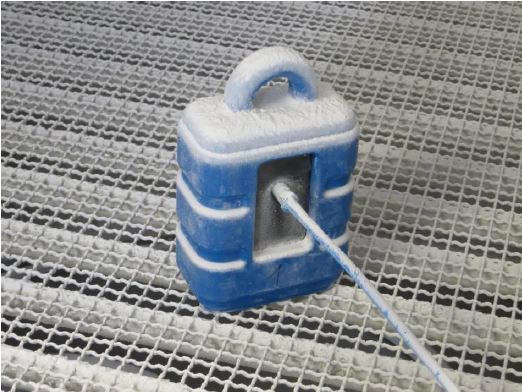

It gets dusty

To ensure that no solid foreign objects penetrate into the housing, the Gateway was dusted for 8 hours. A vacuum of 20mbar and 2kg/m³ talcum were used. However, the Gateway left this completely unmoved and no dust particle managed to penetrate the housing. The IP6x test was successfully passed.

Off into the cool water

Even if a jump into cold water promises an excellent cooling for people on such hot days, electronic devices do not like water at all. The Gateway was exposed to strong jet water (water flow rate 100 l/min) for 3 minutes from a distance of 2.5 to 3 metres. During this test the robust rubber housing did a great job. The water could not infiltrate into the housing and the IPx6 test was successfully completed.

Hold one’s breath

For the IPx8 test the Gateway had to hold its breath. For 5 hours it had to stay one meter under water. Look and be amazed, the Gateway passed this test with flying colours.

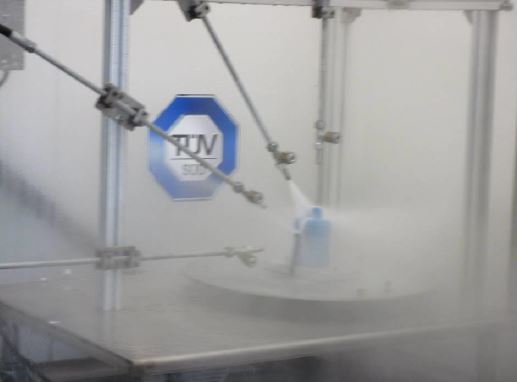

Let the water flow

In the final IPx9 test drastic measures were taken. It had to be possible to somehow get at least one drop of water into the Gateway.

The Gateway was placed on a rotating worktable. 4 high-pressure cleaners pointed threateningly at different angles (0°, 30°, 60°, 90°) to the Gateway. And then the water flows. Water with a temperature of 80° Celsius with a jet pressured of 80 to 100 bar and a distance of 12.5 cm was released onto the Gateway form each position for 30 seconds.

After this difficult test, the Gateway suffered some optical losses and the otherwise so smooth surface was roughened. Nevertheless, no water droplets were able to infiltrate the Gateway.

IP66 / IP68 / IP69

After such a heavy workday our Gateway wishes to return to its natural environment. Receiving data from sensors, for example from H2S sensors or from a pressure sensor, processing them and transmitting them securely to the central server is kind of easy compared to the tasks and tests that the Gateway had to perform in the test laboratory.

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

The meaning of the different IP protection classes

In one of our “Did you know?” articles we have summarized the explanation of the different IP protection classes for you.

If you operate your application in a potentially explosive atmosphere, strict guidelines apply and the device must meet further requirements. Read more in “Did you know: ATEX Zone1 – Why?”