At Microtronics we do not only live M2M but also drink coffee. So of course we painted our coffee machine in Microtronics yellow and equipped it with intelligent technology. As hobby baristas it is especially exciting to us using the Cuptracker to monitor how many litres of coffee are flowing through the Microtronics team’s veins. Coffee machine manufacturers get even more benefits by integrating M2M technology.

Equipped with the right modules every coffee machine becomes a smart connected product. That means that it is constantly communicating with a cloud platform and exchanging data in real-time. The information based on the transmitted data can be read via web or smartphone app.

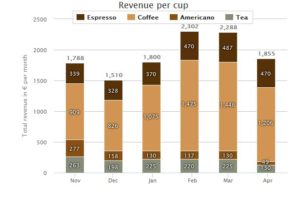

Insights into usage behavior

This gives coffee machine manufacturers deep insights into their customers’ user behaviour. These insights can be used for product optimisations. Furthermore they can give their customers the opportunity to keep track of their individual coffee consumption values. So for example it becomes transparent to costumers how many cups of coffee have been consumed this month, how much water and power were needed to prepare them and how much money have been earned.

Few values, lots of information

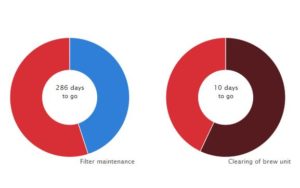

The values water and power consumption are used for the Cuptracker. These values can be used for example for maintenance applications. As soon as one predefined threshold is exceeded or deceeded maintenance staff is alarmed automatically via e-mail, SMS or voice call. Therefore maintenance staff does not have to follow rigid plans but can react individually to failures. This helps to plan maintenance works even more efficiently and helps to save time and money. Additionally end costumers can be informed for example about when the next filter has to be replaced.

The Microtronics Cuptracker uses the XML interface to read out the data from the central cloud server. For the visualisation we used freely available highcharts based on Javascript. So programming the dashboard is peanuts to web developers. The data in standard XML format enable the integration into various applications. Therefore the Cuptracker can be flexibely adjusted to the individual needs of coffee machine manufacturers.

M2M benefits for coffee machine manufacturers at a glance:

- Various visualisation options due to simple access to consumption values via XML interface

- Resource-efficient planning of maintenance works

- Immediate alarming in case of failures via SMS, e-mail or voice call

- Constant overview of a great variety of decentralised coffee machines

- Analysis of user behaviour for future product optimisations

- International usage

- Web services for customers (e.g. smartphone app)

- Secure and stable data transmission via GPRS in real-time