emo

Dynamic Line Rating

What's the solution about?

The safe and reliable operation of overhead high voltage lines (OHTL) in strict compliance with regulatory, technical and economic principles is the backbone of energy supply in interconnected networks.

Deregulation, liberalization and, in particular, the energy turnaround, which is being driven forward, pose enormous challenges for network operators. The energy from non-fossil generation (PV, Aiolic) and the resulting feed-in points require the restructuring of the grids on the one hand and the management of the existing grids under changed fundamentals.

Dynamic Line Rating (DLR) is a method to operate existing network structures much more efficiently.

The heating of the conductor rope by the operating current, as well as the environmental parameters of solar radiation, air temperature/humidity, and in particular the prevailing wind conditions determine the transmittable energy.

The reliable, reduntant, validated and cost-effective real-time measurement of the line temperature under operating conditions and the prevailing climatic conditions as a basis leads to an enormous increase in transmission capacity.

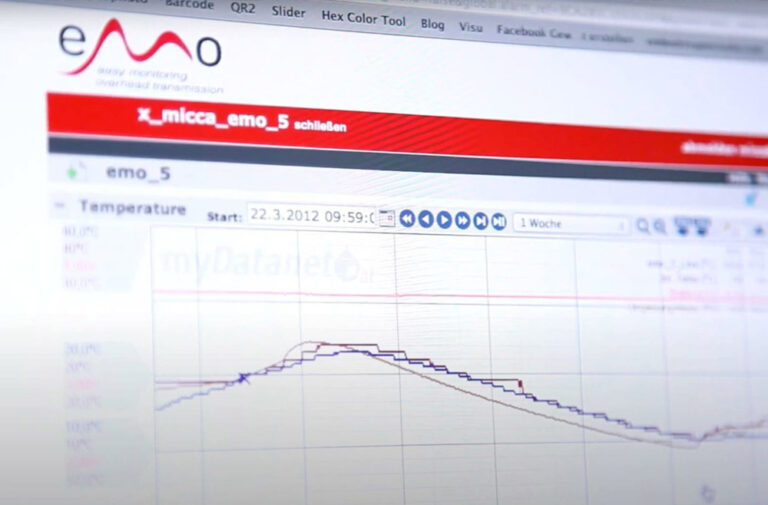

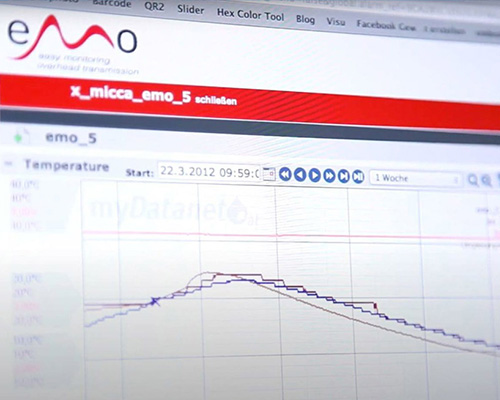

With the measurement and monitoring system emo, micca offers a convincing technical and economic solution for dynamic network management. The heart of the system is the emo_lsh line sensor. The sensor provides transparent, redundant and validated temperature values of the line. Together with the meteorological climate data, the system provides the basis the control parameters of the network.

The measured values are collected by the data logger on the mast (base station) and transmitted to the data platform in a definable form. The transmission path is mobile communications (2G, 4G).

Line sensor emo_lsh: The line sensor emo_lsh is attached to the high-voltage line by means of tear-resistant ties. The unit is equipped with 3 temperature sensors for measuring the line temperature. A reference sensor measures the temperature of the sensor body. With this method, the influences of all environmental conditions as well as the influences of the sensor body itself can be compensated. The measurement data is transmitted to the base station on the pylon using a DSSS 868 transmission unit. The power supply is solved with batteries.

The body of the line sensor is designed as a slot antenna. The default measurement cycle of emo_lsh is set to 1 minute.

The service life without maintenance is typically 10 years. A validation of the conductor rope temperatures is performed in the rope sensor. Only validated measured values are transmitted to the base station. The cable sensors are tested and approved for the voltage levels 110kV, 220 (225)kV, 380 (400)kV (test at TU Graz). The sensor is designed for cable diameters from 16mm to 56mm. Other voltage levels and cable diameters can be offered on request.

These components are used

micca informationstechnologie gmbh was founded in vienna in 2008. The company is active in dynamic line rating in the smart grid environment. The basis for the system is the line sensor emo_lsh, as well as powerful meteorological sensors and an extremely efficient data platform.

By using this compelling measurement method, utilities can significantly increase the efficiency of their existing infrastructure. Efficiency increases in the range of 15% to 35% are realistically achievable. Compliance with the safety reserves defined by the companies determines the degree of efficiency improvement.

-

Schottenring 16/2

1010 Vienna

Austria - office@micca.at

- wwww.micca.at