IGM Messen GmbH

Measuring instruments in harsh environments

What's the solution about?

IGM Messen is a specialist in the collection and evaluation of water management measurement data. It carries out precipitation, discharge, water level, freight and temperature measurements in canals as well as in channels. The company deals with the water management analysis of the collected results and holds the certification as a state-approved testing centre for flow measurement and throttle devices.

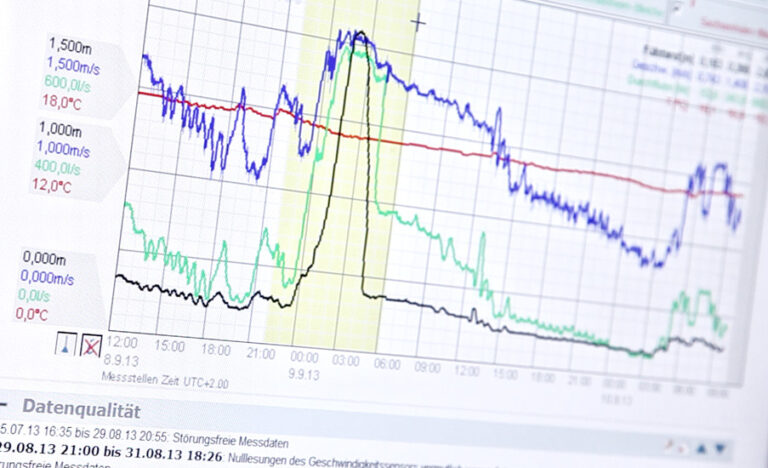

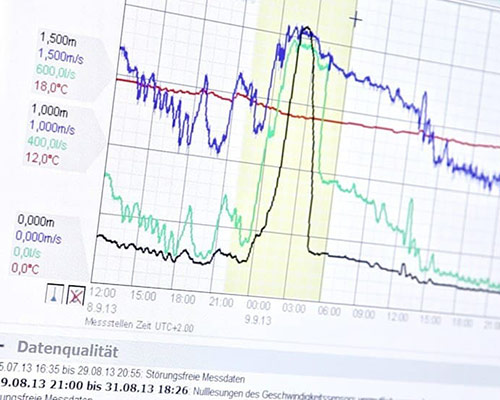

IGM Messen uses its measuring instruments in often difficult measuring environments. In order to be able to guarantee the reliability of the data, it was necessary to read out the measuring devices at least every fortnight. Furthermore, the collected measurement data serve as a basis for engineering planning and must therefore be of particularly high quality and be documented without gaps. IGM Messen was therefore looking for a solution to transmit, store and visualise the data of their measuring devices reliably and in a resource-saving way.

The solution

With an M2M solution from Microtronics, IGM Messen is able to guarantee a high level of reliability of the measurement data. The collected data from the various measuring points are transmitted to a server and can be checked almost in real time. This allows staff to be deployed more efficiently, a larger pool of equipment to be operated, projects to be completed more quickly and maintenance visits to be minimised. The collected measurement data is of such high quality that it can be used for further engineering planning.

The advantages:

- Real-time data transmission via mobile radio

- Permanent access to all measuring points via web browser

- Robust field devices with long-life batteries

- More efficient use of staff

- Minimisation of maintenance operations

- Supervision of an approx. 30% higher pool of equipment

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

These components are used

As a state-approved test centre for flow measurement and throttle devices in Hesse (EKVO) and North Rhine-Westphalia (SüwV-kom), IGM Messen GmbH’s customers include engineering firms as well as private and public sewer network operators; Services include precipitation, discharge, water level, freight and temperature measurements in channels of any size, profile shape as well as in flumes.

-

Breithauptstraße 7

64404 Bickenbach

Germany - igm-mail@igmmessen.de

- +49 6257 6449644

- www.igmmessen.de