Ruwac

Predictive Maintenance & Retrofit

What's the solution about?

IoT enables predictive services for industrial vacuum cleaners. Retrofitting in existing devices such as integration in new vacuums was a prerequisite in the development of the IoT solution.

Ruwac Industriesauger deal with the extraction of all kinds of goods. Whether flammable, explosive or harmless, solid or liquid, chips or dust – Ruwac vacuums it all.

Filters that are too heavily loaded restrict the suction power. The vacuumed material that has been left lying on the ground can cause dangerous situations. The suction power no longer corresponds to the expected quality.

The solution

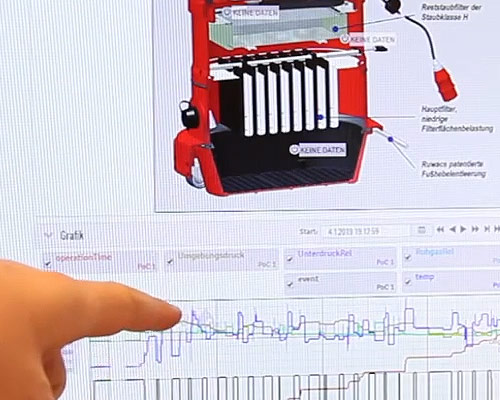

The digitalisation of the vacuum cleaners makes predictive maintenance possible. Ruwac Industriesauger is represented in 20 countries in Europe, America and Asia. With the help of the collected data, the service intervals are optimised. Ruwac gets better insights into how the suction cups behave with different types of suction material. The lessons learned are used to optimise the suction cups and provide customers with even better advice.

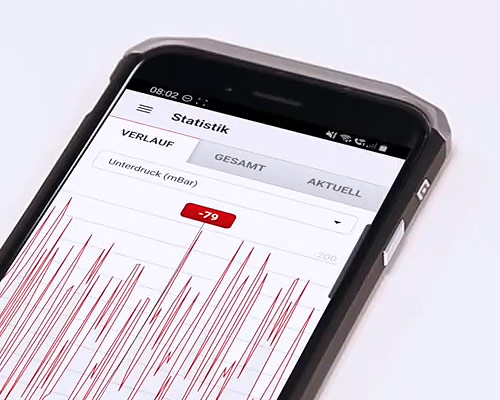

Customers can see the current operating status, operating time, filter load, vacuum and differential pressure via an app.

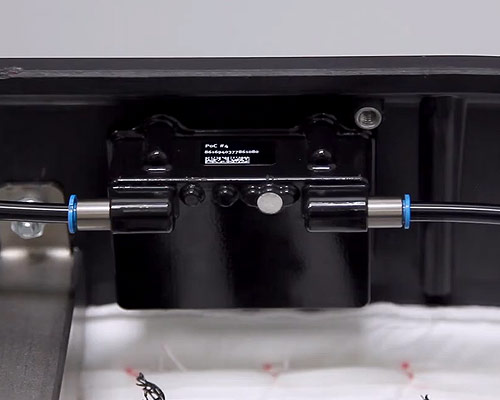

Microtronics has developed the built-in module together with Ruwac. During development, it was important that the solution can be retrofitted in older vacuum cleaners, for example from the 1980s, so that these also have a digital twin.

Mit dem Laden des Videos akzeptieren Sie die Datenschutzerklärung von YouTube.

Mehr erfahren

These components are used

Ruwac was founded in 1976 with the aim of developing vacuum cleaners that solve problems of any kind of vacuumed material and are suitable for the toughest use.

The industrial vacuum cleaners are among the most reliable available in the field of mobile and stationary extraction systems. Whether liquid or solid, harmless or explosive, Ruwac offers a custom-fit solution for every suction material and every application, an optimal extraction system.

From Belgium to Malaysia and Kazakhstan to the USA, Ruwac is available with a well-organised network of 20 worldwide representatives.

-

Westhoyeler Straße 25

49328 Melle

Germany - ruwac@ruwac.de

- +49 5226 9830-0

- www.ruwac.de